Biaxial Testing: Unveiling the Interaction of Normal and Shear Stresses

In the realm of materials science and engineering, understanding the behavior of materials under stress is paramount. While simple uniaxial tests offer valuable insights, they fall short in replicating the complex stress states encountered in real-world applications. Enter biaxial testing, a technique that subjects materials to stresses along two perpendicular axes, enabling a deeper exploration of the interaction between normal and shear stresses.

The Fundamentals of Biaxial Testing

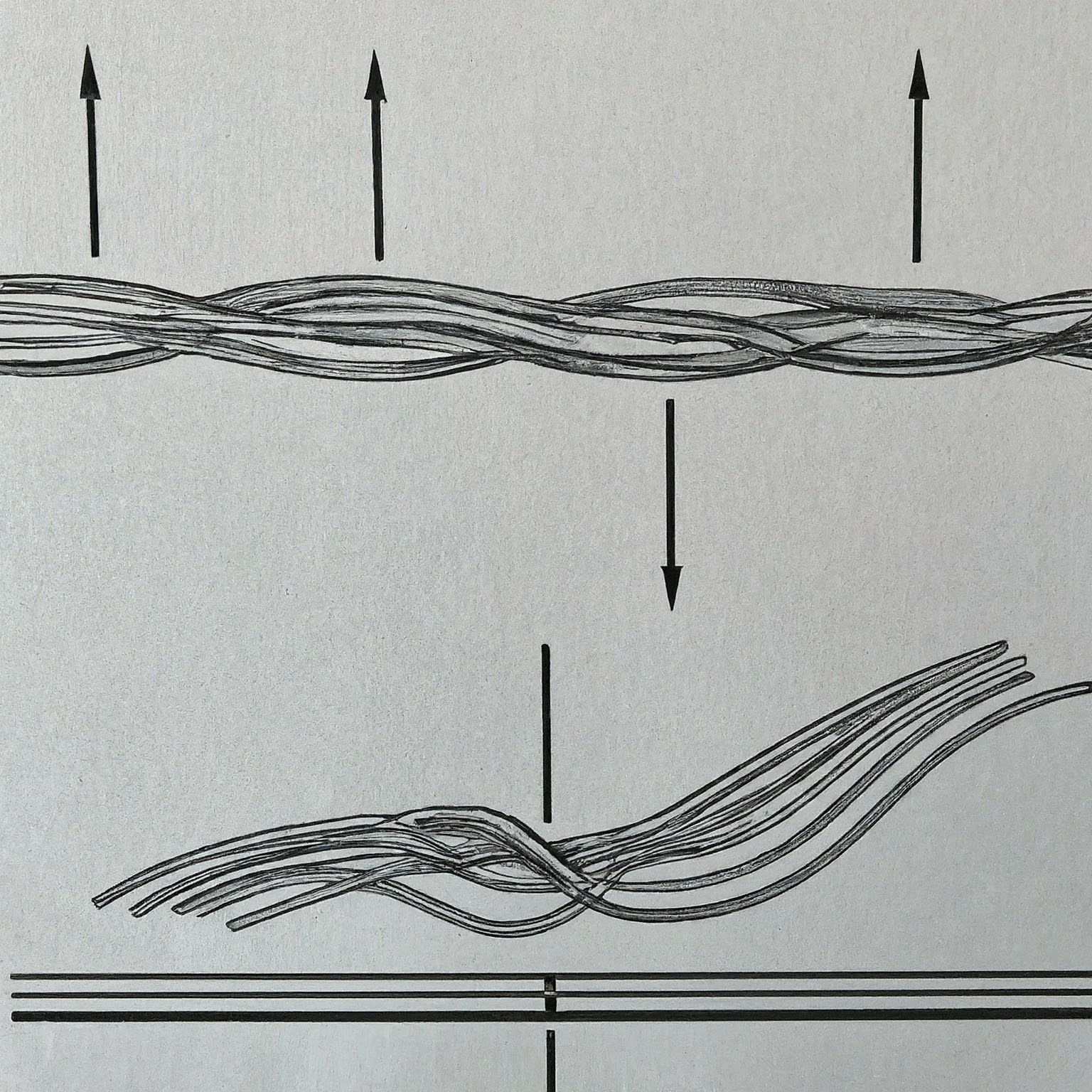

Biaxial testing involves applying loads along two axes, typically labeled as x and y, to a material specimen. This creates a stress state characterized by both normal stresses (acting perpendicular to the surface) and shear stresses (acting parallel to the surface). The primary objective is to observe how the material deforms and potentially fails under these combined stresses.

Normal and Shear Stresses: A Complex Interplay

The interaction between normal and shear stresses is far from trivial. In a biaxial test, the presence of normal stress in one direction can influence the material’s resistance to shear stress in another direction. This phenomenon is known as the normal-shear stress interaction.

For instance, imagine a sheet of metal being pulled in both the x and y directions. The normal stresses generated by these pulls can affect how the metal responds to shear stresses that might try to slide one part of the sheet relative to another. Depending on the material’s properties, the presence of normal stresses could either strengthen or weaken its shear resistance.

Applications and Insights

Biaxial testing has broad applications across various industries:

- Aerospace: Aircraft components experience complex stress states during flight, necessitating biaxial testing to ensure their structural integrity.

- Automotive: Car bodies and engine parts encounter diverse loads, making biaxial testing crucial for evaluating their performance.

- Biomedical: Understanding the biaxial behavior of tissues and implants is vital for designing safe and effective medical devices.

- Civil Engineering: Structures like bridges and buildings face multi-directional forces, requiring biaxial testing to assess their strength and durability.

By conducting biaxial tests, engineers and researchers can gain insights into:

- Yield Criteria: Biaxial testing helps to determine the conditions under which a material starts to deform plastically.

- Failure Mechanisms: Observing how materials fail under biaxial stress reveals their weaknesses and guides the development of more resilient materials.

- Anisotropy: Many materials exhibit different properties in different directions. Biaxial testing can quantify this anisotropy and aid in designing structures that exploit these directional variations.

The Road Ahead

Advancements in biaxial testing techniques and equipment continue to push the boundaries of materials research. The development of sophisticated testing machines, coupled with powerful computational models, enables the simulation and analysis of complex biaxial stress states with ever-increasing accuracy.

In conclusion, biaxial testing stands as a cornerstone of materials characterization, offering a unique window into the intricate interaction of normal and shear stresses. By unraveling this complex relationship, engineers and scientists can design structures and materials that are safer, more efficient, and better equipped to withstand the challenges of the real world.

Note: The concept of biaxial stress and its interaction with shear stress can be mathematically complex. Readers interested in delving deeper can explore theories like the von Mises yield criterion and the Tresca yield criterion.